Ceiling Fan Use ECM NECE88 Series

Main Characteristics :

⚫ Motor Type: 3 Phase internal rotor brushless motor;

⚫ Control Driver Circuit: External circuit, sine wave drive (with lower noise and vibration, but the motor efficiency is also lower);

⚫ Hall Sensor: No;

⚫ Motor Rotation: Can be either in CW or CCW direction as needed;

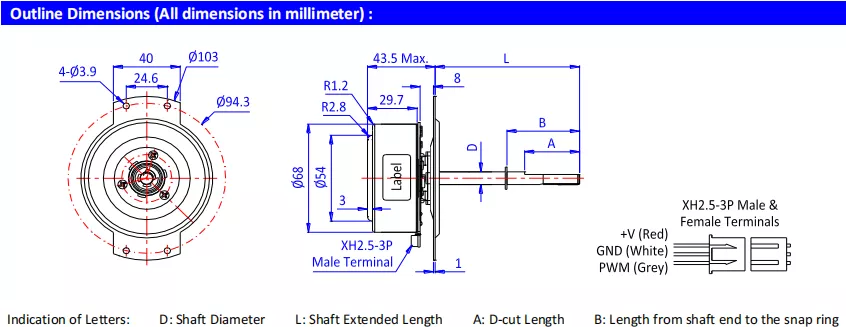

⚫ Fixing of the Fan Blade: By the 8-M6 screw holes in the front of the motor (see from the below drawing).

Typical Applications :

This motor is mostly used for ceiling fan, decoration fan, etc. It can also be used for other applications that need low speeds and low power.